The refill trend - towards circular economy every day

Closed Circuit Economy is a term that, for some time now, has been on the lips of not only environmentalists but also representatives of the business world. When striving for sustainable development, it is vital to ensure that as many goods as possible can be reused. One of the signals of this approach is the refill trend. What is it about? What does it look like in practice, based on the case studies of certain companies?

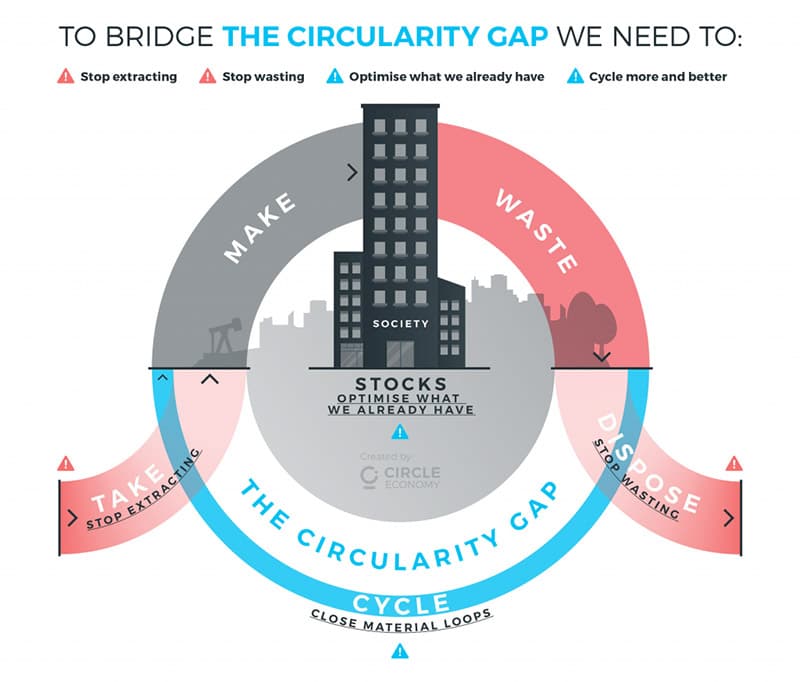

Circular economy as a chance for the planet

According to the definition of the educational portal "Circular Economy in Practice", the circular economy is a model (...) in which products and services are traded within closed loops or cycles. Its main goal is to plan production processes in such a way that it is possible to maintain the greatest value of products, materials and parts.

Thus, it is necessary to manufacture goods with a long service life. Other important issues include: optimising the processes of reusing, refurbishing, reproducing and recycling of all products and materials1.

You should be aware that a closed loop is often the only way to combat the problem of unwanted, non-decomposing waste. It is impossible to infinitely create storage places for packaging that cannot be reused. This is the assumption of companies implementing the refill policy today.

The point is that the packaging used by consumers once should be refilled with a given product. For example, we should top up our coffee or muesli cans by using a refill pack, instead of buying a new can each time.

Refill packs are economical in several respects: they are made of mono materials, with less primary raw material being used, they are lighter and easier to transport, and cheaper to produce, therefore their price on the store shelf is ultimately much lower. In addition, customers are encouraged to carry their own containers with them and by doing so they save resources on a daily basis.

Drugstore solutions for the circular economy

The Yope brand is introducing pro-environmental solutions on the Polish cosmetics market. The company, in its range of products, also offers supplementary packaging. In its points of sale and at the stands with the Yope logo (e.g. in Carrefour Bio stores!), the so-called Swapp vending machines are placed. Liquid products can therefore be poured directly from the machine into your own container. The activities of the Yope brand are promoted with the slogan: "Refill, don't throw away!".

When it comes to companies operating globally, the famous drugstore chain, The Body Shop, intends to introduce refilling and recycling programmes in as many as 400 of its stores2. After the product is used, customers clean the bottles themselves and return them to the store for a refill.

It is also good to know that the French cosmetics brand L'Occitane has committed to introducing 25 refill packages into its product range by 2022. The company is already testing the refill stations in some of its Spanish and German shops.

On the other hand, in the Polish Manufaktura shopping mall in Łódź, in a specially designed area of the Rossmann drugstore, cosmetic dispensers for self-filling of own bottles were set up. In this way, you can replenish your home stock of shower gels, shampoos, dishwashing and washing liquids.

According to the Mintel packaging market marketing agency, in-store "fillers'' are one of the strongest contemporary trends in the stationary trade3. The aforementioned L'Occitane company calculated that the implementation of refilling systems will reduce global plastic consumption by 10%4.

Not just for cosmetics and domestic detergents & cleaners

According to “THE NEW PLASTICS ECONOMY GLOBAL COMMITMENT” report (2019), 36% of the surveyed companies are now implementing their pilot business models for product reuse5. This applies to various sectors, not solely the cosmetic branch.

Example? PepsiCo, which has recently acquired SodaStream, an alternative mechanism for delivering sparkling water using reusable bottles. It is assumed that this should lead to a reduction of around 67 billion plastic bottles by 2025.

Logistics companies are also increasingly following the circular economy trend. The re-use of reusable and returnable packaging is promoted by international brands such as RePack or Loop (TerraCycle purchasing platform)6.

Hope for change?

Once more we find out that huge changes do not always require big steps. A slightly different model of product delivery by the manufacturer combined with the emergence of new habits among consumers can also bring excellent results. Of course, this is not a revolution, but rather an evolution. However, the very fact that brands are seeking more environmentally friendly solutions (even if these are basically CSR-oriented activities) proves it is something positive.

At SILBO, we believe that switching to more ecological packaging is definitely beneficial. Especially if the environmental trend is also followed by the quality confirmed by prestigious certificates.

Check out the full range of our possibilities at www.silbo.pl

----------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1https://gozwpraktyce.pl/slownik/gospodarka-cyrkularna/

2https://packagingeurope.com/Packaging-Trend-Focus-2021-refill-landscape/

3https://www.mintel.com/global-packaging-trends

4https://www.newplasticseconomy.org/assets/doc/Global-Commitment-2019-Progress-Report.pdf

5https://www.newplasticseconomy.org/assets/doc/Global-Commitment-2019-Progress-Report.pdf

6https://www.newplasticseconomy.org/assets/doc/Global-Commitment-2019-Progress-Report.pdf

Zobacz również:

Most frequently read

About company

Silbo – packaging production experts with 20 years of experience in the industry. We support environmental protection on many levels, for example with creating new, biocompostable standards in the field of packaging production. These are the main values on which the activity of SILBO is based: focusing on innovation, ecology and quality issues.

Received certificates